Core Materials

Filters

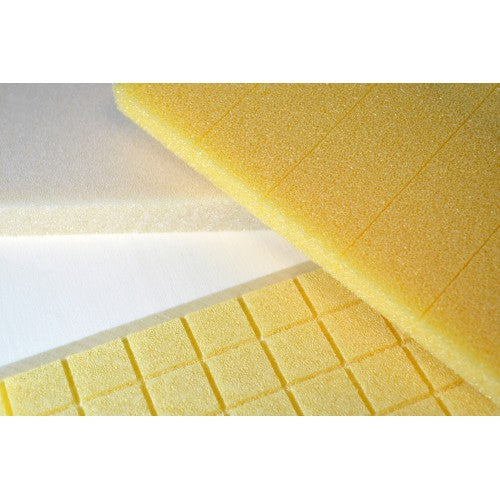

Corecell M80 Contour Scrim 24" X 48"

Noah's MarineIntroducing the Corecell Contour Scrim - the perfect solution for your composite application needs. With its unique combination of high-performance...

View full detailsBalsa Core

Noah's MarineBalsa Core has a honeycomb-like cell structure that’s configured into end-grain panels that can provide optimal properties including high compressi...

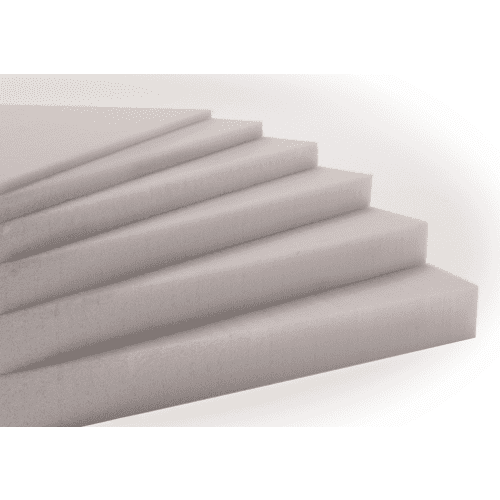

View full detailsCorecell M80 Plain 48" X 96"

Noah's MarineIntroducing Corecell™ M-Foam, the ultimate solution for all your marine composite needs. This innovative foam has been specially developed to provi...

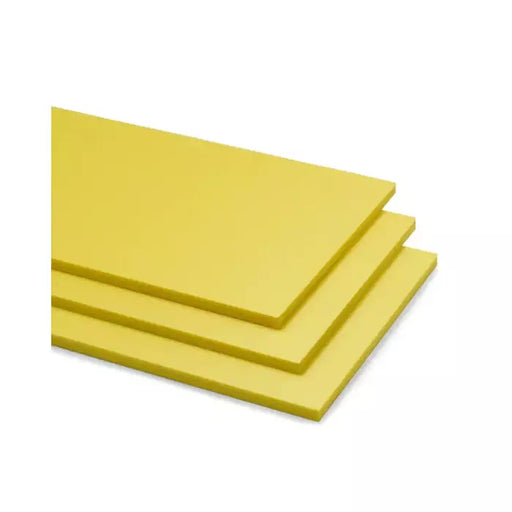

View full detailsGurit G-Pet 90 48" X 96"

Noah's MarineGurit G-PET 90 is a high-performance PET foam core material used in composite sandwich structures. It is a closed-cell, semi-rigid foam that offers...

View full detailsGurit PVC 80 40.2" X 85.8"

Noah's MarineGurit PVC 80 is a structural foam core material used in composite sandwich structures. It is a closed-cell, rigid PVC foam that is lightweight, dur...

View full detailsNida-Core Structural Honeycomb Plain – H8PP 4’X7′

Noah's MarineNida-Core Structural Honeycomb Plain – H8PP 4’X7′ is a high-performance lightweight panel that is designed to provide exceptional strength and dura...

View full detailsCorecell CMAT 3/16" 24" X 48"

Noah's MarineIntroducing Corecell C-Mat 3/16" - the ideal solution for applications requiring thin cores on curved surfaces. This versatile material features fi...

View full details